Idan aka kwatanta da karfe, gilashin fiber ƙarfafa kayan haɗakarwa suna da abu mai sauƙi da yawa da ƙasa da kashi ɗaya bisa uku na na karfe.Koyaya, dangane da ƙarfi, lokacin da damuwa ya kai 400MPa, sandunan ƙarfe za su fuskanci damuwa mai ƙarfi, yayin da ƙarfin ƙarfi na kayan haɗin fiber na gilashin zai iya kaiwa 1000-2500MPa.Idan aka kwatanta da kayan ƙarfe na gargajiya, kayan haɗin fiber na gilashi suna da tsari iri-iri da bayyananniyar anisotropy, tare da ƙarin ingantattun hanyoyin gazawa.Binciken gwaji da ka'idoji a karkashin nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'in nau'in kifi) na nau'ikan bincike na gwaji da bincike na gwaji na iya ba da cikakkiyar fahimta game da kaddarorinsu na injina, musamman idan aka yi amfani da su a fannoni kamar na'urorin tsaron ƙasa da sararin samaniya, waɗanda ke buƙatar zurfafa bincike kan halayensu da kaddarorin injina don biyan bukatunsu a cikin yanayin amfani.

Abubuwan da ke biyowa suna gabatar da kaddarorin injiniya da bayanan lalacewa na kayan haɗin fiber gilashin, samar da jagora ga aikace-aikacen wannan kayan.

(1) Kaddarorin Tensile da bincike:

Bincike ya nuna cewa kaddarorin inji na fiber gilashin ƙarfafa kayan haɗin gwal na resin epoxy sun nuna cewa ƙarfin ƙarfi a cikin layi ɗaya na kayan yana da girma fiye da na a tsaye na fiber.Sabili da haka, a cikin amfani mai amfani, jagorancin gilashin gilashin ya kamata a kiyaye shi daidai kamar yadda zai yiwu tare da jagorancin kullun, yana amfani da cikakkiyar kayan aiki mai kyau.Idan aka kwatanta da karfe, ƙarfin juzu'i yana da mahimmanci mafi girma, amma yawancin ya fi ƙasa da na karfe.Ana iya ganin cewa, Ƙaƙƙarfan kayan aikin injiniya na kayan haɗin fiber na gilashi suna da girma.

Bincike ya nuna cewa ƙara yawan fiber ɗin gilashin da aka ƙara zuwa kayan haɗin gwiwar thermoplastic a hankali yana ƙara ƙarfin ƙarfin kayan haɗin gwiwa.Babban dalili shi ne cewa yayin da abun ciki na gilashin gilashi ya karu, yawancin filaye na gilashi a cikin kayan da aka haɗa suna fuskantar dakarun waje.A lokaci guda, saboda karuwa a cikin adadin gilashin gilashin, matrix resin matrix tsakanin gilashin gilashin ya zama bakin ciki, wanda ya fi dacewa da gina gine-ginen gilashin gilashi.Sabili da haka, Ƙarfafa abun ciki na fiber gilashi yana haifar da ƙarin damuwa da za a watsa daga resin zuwa gilashin gilashin a cikin kayan da aka haɗa a ƙarƙashin nauyin waje, da kyau inganta kayan aikin su.

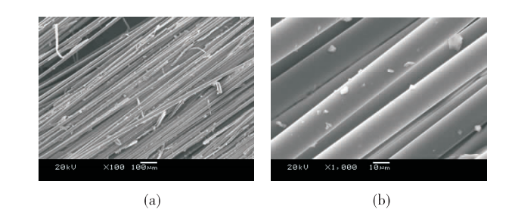

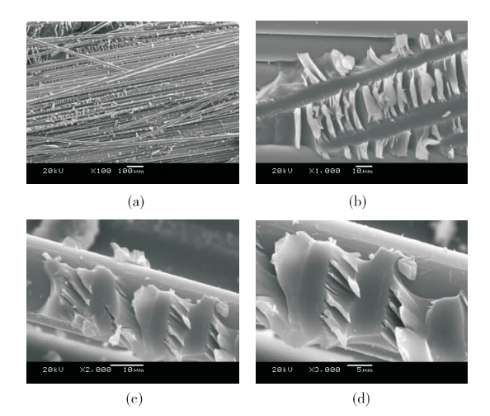

Bincike kan gwaje-gwajen tensile na gilashin fiber unsaturated polyester composite kayan ya nuna cewa gazawar yanayin gilashin fiber ƙarfafa kayan haɗakarwa shine haɗuwa da gazawar zaruruwa da matrix resin ta hanyar duban microscopy na lantarki na sashin tensile.Fagen karaya ya nuna cewa ana fitar da filaye masu yawa na gilashin daga cikin matrix na resin da ke sashin juzu'i, kuma saman filayen gilashin da aka ciro daga matrix na resin ɗin yana da santsi da tsabta, tare da ɓangarorin resin kaɗan da ke manne da saman. na gilashin zaruruwa, The yi ne gaggautsa karaya.Ta hanyar haɓaka haɗin haɗin kai tsakanin filayen gilashi da guduro, ƙarfin haɗawa na biyu yana haɓaka.A ɓangaren juzu'i, ana iya ganin yawancin gutsuttsuran guduro na matrix tare da ƙarin haɗakar filayen gilashi.Ƙarin lura da haɓaka yana nuna cewa babban adadin matrix resin bond a saman filayen gilashin da aka fitar kuma suna gabatar da tsefe kamar tsari.Ƙarƙashin ɓarna yana nuna ɓarna ductile, wanda zai iya cimma mafi kyawun kayan aikin injiniya.

(2) Lankwasawa aiki da bincike:

An gudanar da gwaje-gwajen gajiyar maki uku akan faranti marasa jagora da jikkunan simintin gyare-gyare na fiber gilashin ƙarfafa kayan haɗin gwiwar guduro epoxy.Sakamakon ya nuna cewa lanƙwasawa na biyu ya ci gaba da raguwa tare da karuwar lokutan gajiya.Koyaya, lanƙwasawa na filayen gilashin yana ƙarfafa faranti marasa madaidaici ya fi na jikkunan simintin gyare-gyare, kuma raguwar taurin ya kasance a hankali.An sami ƙarin lokutan gajiya na fashewa da ke bayyana akan lokaci, yana nuna cewa fiber gilashi yana da ingantaccen tasiri akan aikin lanƙwasawa na matrix.

Tare da gabatarwar filaye na gilashi da karuwa a hankali a cikin ƙananan juzu'i, ƙarfin lanƙwasawa na kayan haɗin gwiwar kuma yana ƙaruwa daidai.Lokacin da juzu'in ƙarar fiber ya kasance 50%, ƙarfin lanƙwasa shine mafi girma, wanda shine 21.3% sama da ƙarfin asali.Duk da haka, lokacin da ƙananan ƙwayar fiber ya kasance 80%, ƙarfin lanƙwasawa na kayan haɗin gwiwar yana nuna raguwa mai mahimmanci, wanda ya fi ƙasa da ƙarfin samfurin ba tare da fiber ba.An yi imani da cewa, ƙananan ƙarfin abu na iya zama saboda microcracks na ciki da ɓoyayyiya suna toshe tasiri mai tasiri ta hanyar matrix zuwa zaruruwa, kuma a ƙarƙashin sojojin waje, microcracks da sauri fadada don samar da kuskure, kyakkyawan haifar da lalacewa. Interface bonding na wannan gilashin fiber composite abu, yafi dogara a kan danko kwarara na gilashin fiber matrix a high yanayin zafi nannade zaruruwa, da kuma wuce kima gilashin zaruruwa ƙwarai hana danko kwarara daga cikin matrix, haifar da wani mataki na lalacewa ga ci gaba tsakanin. da musaya.

(3) Ayyukan juriya na shiga:

Yin amfani da filaye mai ƙarfi na gilashin ƙarfafa kayan haɗin gwiwa don fuska da baya na sulke na amsawa yana da mafi kyawun juriyar shigar ciki idan aka kwatanta da na gargajiya gami da ƙarfe.Idan aka kwatanta da gami da ƙarfe, kayan haɗin fiber na gilashi don fuska da baya na sulke masu fashewa suna da ƙananan ragowar gutsuttsura bayan fashewa, ba tare da wani ikon kisa ba, kuma yana iya kawar da wani ɓangare na sakamakon kisa na biyu na fashewar sulke.

Lokacin aikawa: Nuwamba-07-2023